What are the components of the piston connecting rod set?What is the role of each?

The piston connecting rod group changes the reciprocating motion of the piston into the rotary motion of the crankshaft, and changes the force acting on the piston into the external output torque of the crankshaft to drive the vehicle wheels to rotate. It is the transmission part of the engine. It transmits the pressure of combustion gas to the crankshaft, which makes the crankshaft rotate and output power. The piston connecting rod group is mainly composed of piston, piston ring, piston pin, connecting rod and connecting rod bearing bush.

Piston

1. Function of piston

The main function of the piston is to bear the gas pressure of the cylinder and transmit this force to the connecting rod through the piston pin to push the crankshaft to rotate. It transmits the pressure of the combustion gas to the crankshaft to make the crankshaft rotate and output power; The top of the piston, cylinder head and cylinder wall also form a combustion chamber.

2. Composition of plug

The piston is mainly composed of the top, head and skirt. The shape of the piston top is related to the combustion chamber. The head of gasoline engine piston generally adopts flat roof, which has the advantages of small heat absorption area and simple manufacturing process. In order to change the formation of the mixture, some use the concave roof, and the size of the concave can also adjust the engine compression ratio.

The piston head is above the piston ring groove. It has three functions: bear the gas pressure and transmit it to the connecting rod; Cylinder sealing with piston; The heat absorbed by the piston crown is transferred to the cylinder wall through the piston ring. The head is cut with several ring grooves to install piston rings. Gasoline engines generally have 2-3 ring grooves, the upper 1-2 ring grooves are used for gas rings, and the lower one is used for installing oil rings. Many radial holes are drilled on the bottom surface of the oil ring groove, so that the excess oil scraped by the oil ring flows back to the oil pan through the holes.

The piston skirt refers to the part from the lower end of the oil ring groove to the bottom of the piston. Its function is to guide the piston to and fro in the cylinder and bear side pressure. When the piston is working, the combustion gas pressure acts on the top of the piston, while the reaction force of the piston pin acts on the pin seat hole of the head. The resulting deformation is that the skirt diameter increases along the axis of the piston pin seat (stress deformation). The side pressure N deforms the piston skirt; The metal pile near the piston pin seat hole has a large amount of thermal expansion, resulting in a large amount of thermal expansion in the direction of the piston pin seat hole when the skirt is deformed. The skirt is elliptical. In order to ensure the contact between the piston and the cylinder wall in the cold state, the piston skirt is slotted. Because the piston is heated along the axis and the mass distribution is uneven, the piston is made into an approximate conical shape with small size at the top and large size at the bottom.

The piston pin seat hole is also one of the components of the piston. It transmits the gas force at the top of the piston to the connecting rod through the piston pin. The pin seat hole is usually connected with the piston with ribs to improve its rigidity. There is a snap ring groove for installing elastic snap ring in the pin seat hole. The snap ring is used to prevent the piston pin from axial movement during operation.

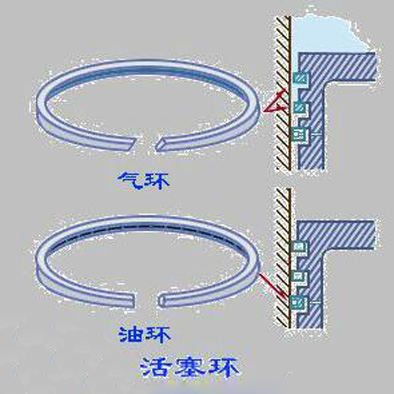

Piston ring

Piston ring includes gas ring and oil ring.

1.Gas ring (function, common fault, structure)

The function of the gas ring is to ensure the sealing between the piston and the cylinder wall, and prevent high-temperature and high-pressure gas from entering the crankcase; At the same time, most of the heat at the top of the piston is transferred to the cylinder, and then taken away by cooling water or air.

The piston ring is affected by the high temperature and pressure of the gas in the cylinder when it works. Its temperature is high, and it moves at high speed in the cylinder. In addition, the high temperature of the engine oil deteriorates, the lubrication condition deteriorates, and its wear is serious. After piston ring wear and failure, the engine has difficulties in starting, insufficient power, increased crankcase pressure, large oil consumption, black smoke from exhaust, and serious carbon on the piston edge.

Due to the uneven wear of the cylinder, it becomes tapered and elliptical. The piston reciprocates in it, producing a tension and contraction movement along the neck direction, which makes the ring easy to break due to bending stress, resulting in engine seizure, cylinder pulling and engine failure.

Piston rings are generally cast with alloy cast iron. The working surface of the first gas ring is generally coated with porous chromium. (Porous chromium has a high hardness and can store a small amount of engine oil). Other general tin plating or phosphating can improve the running-in performance.

There is a notch on the piston ring, and its free state is not circular, and its size is larger than the inner diameter of the cylinder. So after it is installed into the cylinder with the piston, it will generate elastic force and close to the cylinder wall, so that the gas cannot pass through the gap between the contact surface of the ring and the cylinder wall. The cut is generally 0.25-0.8mm.

2.Oil ring

The oil ring is mainly used for oil scraping, oil distribution and auxiliary sealing. The oil ring is used to scrape off the excess oil on the cylinder wall and apply a uniform oil film on the cylinder wall, which can not only prevent the oil from flowing in, but also reduce the wear and friction resistance between the piston and the cylinder.

Oil ring

The oil ring is divided into ordinary oil ring and combined oil ring. The ordinary oil ring is generally made of cast iron. There is a groove in the middle of its outer circle, and many oil drain holes are processed at the bottom of the groove. The combined oil ring is composed of oil scraper and two elastic lining rings. The axial lining ring is clamped between the second and third oil scraper.

oil ring

Piston pin

The piston pin is used to connect the piston and the small end of the connecting rod and transmit the force of the gas borne by the piston to the connecting rod. The piston pin is a hollow cylinder, which is generally carburized and quenched with low carbon steel and low carbon alloy steel or quenched with 45 # medium carbon steel at high frequency.

According to the different fixing methods of piston pin, it can be divided into full floating type or semi-floating type. The connection between piston pin and piston pin seat hole is generally "fully floating", that is, during engine transfer, the piston pin can not only be in the small end bushing hole of connecting rod, but also slowly rotate in the pin seat hole, so that the wear of each part of the piston pin is relatively uniform.

Connecting rod

1. Role of connecting rod

The function of the connecting rod is to connect the piston and the crankshaft, convert the reciprocating motion of the piston into the rotary motion of the crankshaft, and transmit the force borne by the piston to the crankshaft.

2. Composition of connecting rod

The connecting rod is generally composed of small end, rod body and large end.

The connecting rod is generally made of medium carbon steel or alloy steel. The small end of the connecting rod is connected with the piston pin. There is relative movement between the connecting rod and the pin during operation. There is a bushing (bronze) in the small end hole. A small hole (oil passage) is drilled on the small end of the connecting rod and the bushing to lubricate the small end and the piston pin.

The connecting rod body is usually made into I-shaped section to increase its strength and rigidity. There is an oil lubrication passage in the middle.

The big end of the connecting rod is connected with the crank pin of the crankshaft. The big end is generally split. The separated part is called the connecting rod cap, which is fastened to the big end of the connecting rod with special connecting rod bolts. Connecting rod cap and connecting rod big end are combined with hole lining. In order to prevent assembly error, there is matching mark on the same side. The surface of the big end hole has a high degree of finish, so as to fit closely with the connecting rod bearing bush. The large end of the connecting rod is also milled with a locating hole, and the large end of the connecting rod has an oil hole.

The connecting rod big end can be divided into flat cut and oblique cut according to the split plane. Generally, the diameter of the connecting rod big end of the gasoline engine is smaller than the diameter of the cylinder, and the flat cut is adopted; The diesel engine has a large stress, and its big end diameter is larger than the diameter of the cylinder. It adopts an oblique cut, which generally forms an angle of 30~60 ℃ with the connecting rod axis.

Connecting rod bolts are important parts subject to alternating stress. They must be firm and reliable during installation. They must meet the tightening torque specified by the factory and be tightened in 2-3 times.

connecting rod