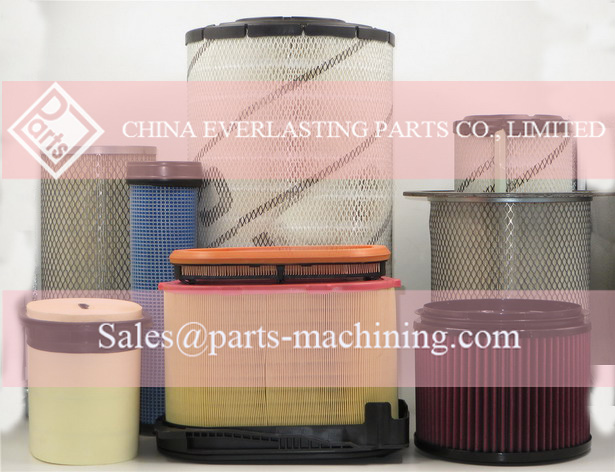

There are two types of air filter, namely dry and wet.

Dry air filter through a dry filter, (such as a paper filter)the air filter separat impurities from air. Light vehicles (including cars, mini-cars) used for single-stage air filter usually. The air filter including oval or elliptical shape and flatbed. The filter material is filter paper or nonwoven fabric. Filter cover with metal or polyurethane, the shell material is metal or plastic. At rated air volume flow rate the filtration efficiency should be not less than 99.5%. Heavy vehicles work in poor working conditions, the air filters must be a majority air filter. The first stage cyclone pre-filter (such as a blade ring, swirl tubes, etc.), used to filter impurities coarse particles, filtration efficiency above 80%, the second stage fine filter is a porous paper filter (commonly referred to as primary filter), the filtration efficiency of 99.5%. After the main filter and a safety cartridge, its role in the installation and replacement of the main filter, or prevent dust from entering the engine when the main element accidental damage. Multi-core safe material non-woven fabric, but also the use of filter paper.

The wet air filters Including oil-immersed wet filter and Oil bath Filter. Oil-filled through a filter, separating out impurities from the air, the filter material with metal wire fabric, there are foam. Oil bath is sucked into the dust laden air into the oil tank was removed most of the dust, and then in the air up through the mist with a metal wire wound into a cartridge when further filtration, oil droplets and was stopped by the dust return together to the oil tank.

Precautions

Generator air filter: The main filter is an intake device , filter particles and impurities from the air the piston generators work inhaled airborne, The device consists of two parts consisting of housing and filter element. The main requirement of the air filter is high filtration efficiency, low flow resistance, can be used continuously for a long time without maintenance. When the generators work, The intake air containing dust and other impurities will be increased wear parts, it must be equipped with air filters.

The Air Filters including inertial, filtered and oil bath 3 type: inertial Air Filter: Because of the density of particles and impurities larger density of air, when the rotation of particles and impurities in the air or during hard cornering, centrifugal force of the energy impurities are separated from the gas stream. Filter: guide the air flow through the metal strainer or filter paper, and particulate impurities barrier and adhere to the filter. Oil bath: There have oil pan provided at the bottom of the air filter, air swerved oil shocks, the particles and separation of impurities in the oil and viscous, and was stirring up the oil droplet with the air flow through the filter, and adhere on the filter. Purpose of the air flows through the filter can be further adsorbed impurities, so as to achieve the filtration.

Generators air filter replacement cycle: Commonly used generator sets replaced once every 500 hours; standby generators work 300 hours or six months to replace one. Usually can be taken down by a wind blowing air gun can also be extended replacement cycle of 200 hours or three months when the generator set maintenance.

Filters for filtration requirements: requires regular factory production of filter, do not need the famouse brand Air filter, but have to avoid to use the low efficiency air filter.

Replacement cycle:

Generally advise clients to each driving 15,000 km replacement. Vehicle air filters often work in harsh environments should not be replaced once over 10,000 km. (Desert, construction sites, etc.)

Air filter life, the car is about 15,000 km, commercial vehicles is about 20,000 km.

Filtration requirements:

1. High filtration precision: filter out all larger particles (> 1- 2 um)

2. The high filtration efficiency: reducing the quantity of particles through the filter.

3. To prevent engine wear occurs earlier. Air flow meter to prevent damage!

4. Low pressure, ensure that the engine has the best fuel ratio. Reduce the filtration loss.

5. The filtration area, high dust capacity, long service life. Reduce operating expenses.

6. Install the small space, compact structure.

7. Wet quite high, suck deflated phenomenon appears to prevent the filter, causing the filter breakdown.

8. retardant

9. reliable sealing performance

10. Good value for money

11.The metal-free structure. Environmentally friendly, reusable. Conducive to storage.

Related reading: Excavator air filter 7Y-0404 CAT air filter 2S-1286