What are the common faults of automobile brake system?

1.Fault phenomenon: the pedal does not rise when the brake pedal is pressed, and there is no resistance;

Judge the reason: check whether the brake fluid is missing; Check whether there is oil leakage at the brake wheel cylinder, pipeline and joint; Whether the master cylinder and slave cylinder parts are damaged;

2.Fault phenomenon: continuously press the brake, the braking effect is improved, and the pedal returns to a higher position;

Judge the reason: the clearance between the friction plate and the brake drum is too large;

3.Symptom: The pedal position is very low; If you step on it again, this position cannot be lifted and feels stiff;

Judge the cause: the main cylinder is blocked;

4.Fault phenomenon: brake deviation;

Judge the reason: if the vehicle moves to the left, the right wheel brake is invalid, and vice versa;

5. Fault phenomenon: the free stroke of brake pedal is too small;

Reason for judgment: adjustment required;

6.Fault phenomenon: the brake pedal is pressed to the bottom, and the braking effect is not good; Continuous braking, the effect is not improved, and the pedal gradually rises;

Judge the reason: the brake system is mixed with gas;

7.Symptom: When the brake is pressed continuously, the pedal position rises or falls;

Determine the cause: oil leakage;

8.Fault phenomenon: the pedal height is normal, not soft or sinking, but the braking effect is not good;

Judge the cause: the clearance between the friction plate and the brake drum is too large or there is oil stain;

9.Fault phenomenon: the brake drum (disc) is hot when the vehicle travels a certain distance;

Determine the cause: check the brake master cylinder, brake wheel cylinder or pipeline;

10.Fault phenomenon: the brake fluid level rises slowly;

Determine the cause: loosen the bleed screw and observe the return of the brake shoe. If the brake shoe returns, dredge the oil pipe; If the brake shoe does not return, remove and check the brake wheel cylinder.

Methods of automobile braking

1)Emergency braking. Emergency braking is a stop measure that the driver must take in order to stop the vehicle in the shortest time when encountering an emergency during driving.

During emergency braking, hold the steering wheel with both hands, quickly lift the right foot from the accelerator pedal, and press the brake pedal firmly. If necessary, pull the parking brake lever to stop the vehicle within a limited distance and time.

Emergency braking is an emergency measure taken to deal with some emergencies in operation, which is used for emergencies. When heavy vehicles are driving, the road traffic conditions should be handled in advance, and the predictive braking should be used as much as possible to avoid emergency braking.

2)Predictive braking. When the vehicle finds it difficult to pass the road ahead, it can release the accelerator pedal in advance and use the idle running of the engine to force the vehicle to slow down. Then, press the brake pedal continuously or intermittently according to the specific situation to further reduce the vehicle speed. The braking application during vehicle driving is mainly predictive braking to slow down the vehicle.

Predictive braking is mainly used to stop at a predetermined place and handle the speed control during prediction or queuing.

3)Engine braking. Engine braking means that when driving at a certain speed, the driver presses the accelerator pedal instead of the clutch pedal, and only relies on the engine idle traction force to force the vehicle to decelerate, thus achieving the purpose of braking.

Engine braking is suitable for downhill driving in mountainous areas. This is a braking method to avoid braking heat attenuation caused by frequent use of braking. Engine braking is also often used to predict vehicle coasting before braking and stopping. When driving on wet roads such as mud, ice and snow, the engine brake should also be used as much as possible to effectively prevent sideslip.

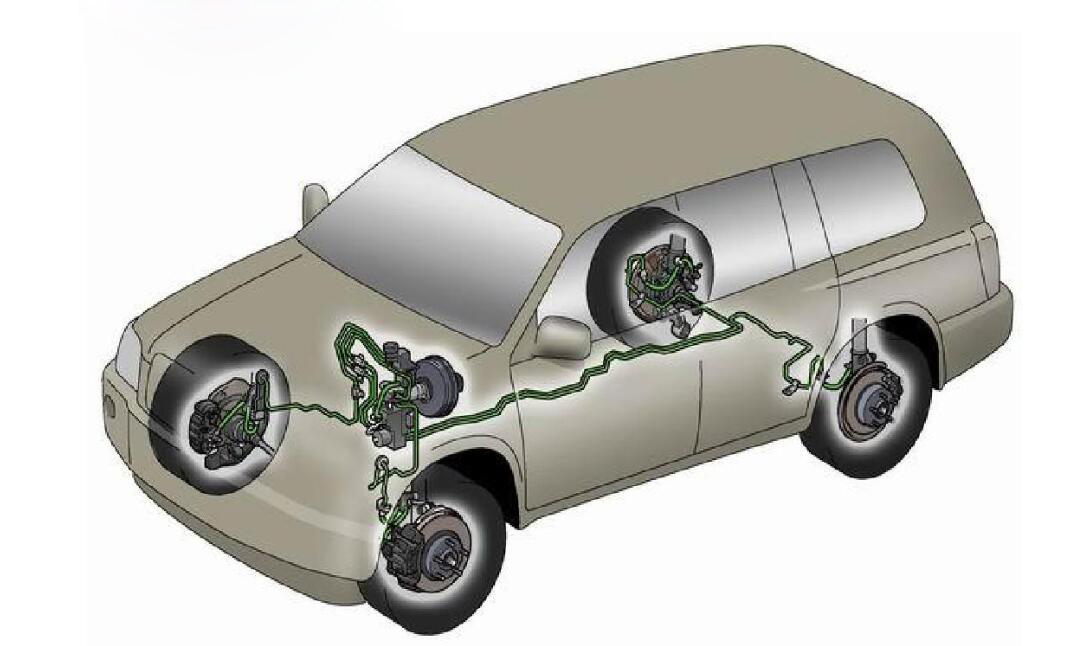

Brake system maintenance skills

1.Cleaning and maintenance of brake system

The vehicle shall be cleaned and maintained every 50000 km or when the ABS response is too early or too slow. Remove the harmful sludge paint film in the system, eliminate the danger of working failure under ultra-high temperature or ultra-low temperature, effectively prevent the deterioration and expiration of the brake fluid, and completely replace the old brake fluid.

2.Cleaning and maintenance of transmission (automatic transmission)

Under normal conditions, the vehicle should be cleaned and maintained once every 20000km-25000km, or when the transmission slips, the water temperature is too high, the shift is slow and the system leaks. Remove harmful sludge and paint film deposits, restore the elasticity of the sealing gasket and O-ring, make the transmission shift smoothly, improve the power output, and completely replace the old automatic transmission oil.

3.Cleaning and maintenance of power steering system

The vehicle needs to be cleaned and maintained every 40000 km to 450000 km, or in the case of difficult steering and system leakage, the power steering gear accessories need to be cleaned and maintained after being replaced. Remove the harmful sludge and paint film in the system, eliminate the steering difficulty under low temperature, stop and prevent the power steering fluid leakage, eliminate the steering noise, and completely replace the old brake steering fluid.

4.Detailed maintenance of lubrication system

The main function of the lubrication system is to effectively lubricate all parts of the automobile engine to prevent excessive wear. Under normal conditions, vehicles need to be cleaned and maintained every 5000km-10000km. If the engine noise is too loud, the acceleration is weak, and the water temperature is too high, it also needs to be cleaned and maintained once. Clean the oil sludge and other deposits inside the engine, avoid the oxidation and thickening of engine oil under high temperature, reduce the wear of engine components, extend the engine life and improve the engine power.

5.Cleaning and maintenance of cooling system

Generally, cars should be cleaned and maintained once in winter and summer, once every 6 to 8 months during normal driving, or once when the water temperature is too high, water leakage and boiler boiling. Remove the traces and scale that cause the engine to overheat, prevent harmful corrosion, avoid and stop the leakage of seals and water tanks, and completely replace the old coolant.

6.Cleaning and maintenance of the fuel system (that is, cleaning the carbon deposits on the nozzle and valve)