What are the components of the hydraulic suspension system?What is the function?

The tractor hydraulic suspension system is used to connect the hanging or semi-hanging agricultural implements, and control the lifting, lowering and operating depth of agricultural implements.

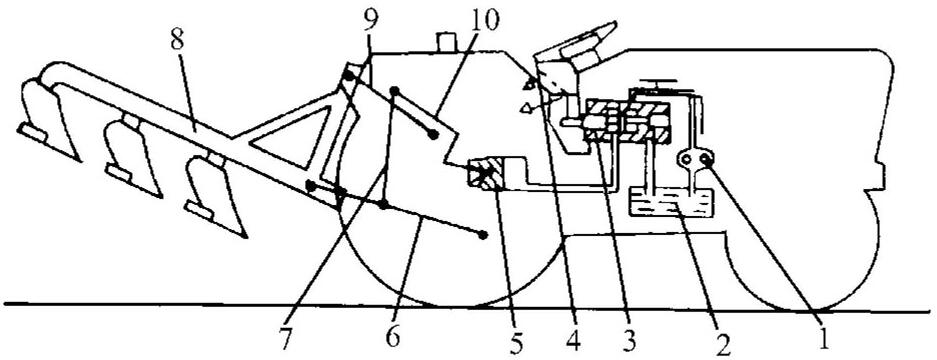

(1) The tractor hydraulic suspension system consists of hydraulic system and linkage (Fig. 3-31).

(Fig. 3-31).Schematic diagram of hydraulic suspension device

1. Oil pump 2. Oil tank 3. Distributor 4. Operating handle 5. Oil cylinder 6. Pull rod 7. Lift rod 8. Agricultural tool 9. Top link 10. Lift arm

The hydraulic system is mainly composed of oil pump, distributor, oil cylinder, auxiliary devices (oil tank, oil pipe, filter, etc.) and control mechanism.

The linkage is mainly composed of lifting arm, upper link, lifting rod and lower link.

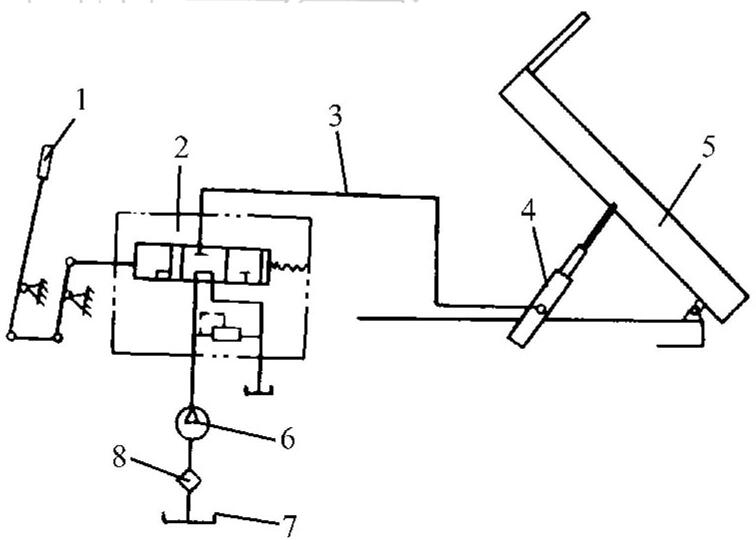

(2) Many small tractors are equipped with hydraulic dump mechanism to improve transport efficiency and reduce labor intensity. The hydraulic dump mechanism is generally composed of oil pump, distribution valve, control rod, hydraulic oil tank, oil pipe, hydraulic oil cylinder and auxiliary support mechanism (Fig. 3-32). During operation, the hydraulic oil pump is driven by the power output shaft of the transmission or other devices to pump the hydraulic oil from the oil tank, and press the pressure oil into the working chamber of the oil tank through the distributor to lift the carriage and realize automatic dumping; After the goods are dumped, operate the distributor to stop supplying oil to the oil tank, and connect the oil tank with the oil tank at the same time, so that the carriage can be reset under the action of its own weight.

Fig. 3-32 Structural diagram of hydraulic dump

1. Control lever 2. Distribution valve 3. Oil pipe 4. Oil cylinder 5. Carriage 6. Oil pump 7. Oil tank 8. Filter

How to operate and use the hydraulic suspension system correctly?

The function of hydraulic suspension system is:

When the tractor is transferred, lift the suspended agricultural tools; Adjust the depth of farming tools during farming; The output pressure oil is used by supporting tools (such as dump trailer). It has powerful adjusting handle and position adjusting handle. When the hydraulic suspension system is not used, both handles should be put at the lowest position (do not put both handles at the same time in the lifting position)

Pay attention to the following points during operation:

(1) Correctly hook agricultural tools

When hitching agricultural implements, place the lifting control handle in the lowering position. Start the tractor to slowly reverse to approach the farm tool. First connect the farm tool with the left lower link, and then connect the right lower link. If the tool shaft is not aligned with the pull rod hole, turn the adjusting tube of the right diagonal pull rod to change its length, and finally connect the upper pull rod. All pull rods are locked with locking pins after connection. The front and rear horizontal positions of agricultural implements are adjusted by the top link. Turn the intermediate solenoid during adjustment and lock it with nuts after adjustment. The left and right horizontal positions of agricultural tools are adjusted by the diagonal pull rod, and the length of the left diagonal pull rod can also be adjusted if necessary.

(2) Lifting and transporting agricultural tools correctly

Both the force adjusting handle and the position adjusting handle can control the lifting and lowering of agricultural tools, but they are used in different situations. When one handle is used, the other handle must be placed in the raised position and locked. Move the handle forward to lower the implement, and move the implement backward to raise it. The time required for lifting and lowering agricultural implements is generally increased to 3 seconds and decreased to about 1 second. The tractor has been adjusted before leaving the factory and needs no change during use.

When the tractor is working in the field, it should raise the farm tools first, then turn, and then lower the farm tools when entering the straight line. It is forbidden to use the force adjusting handle to lower the agricultural tools on the hard road surface, so as to avoid damaging the agricultural tools due to the falling speed too fast.

When the tractor suspends agricultural implements for long distance transfer, screw in the hand wheel of the intercepting valve on the left side of the elevator to lock the agricultural implements in the lifting position, put the force and position adjustment handle in the lowering position, and then put the power take-off active handle in the "open" position to stop the power take-off shaft from working, and then put it back in the "close" position after the transfer. When the tractor is towing the trailer for transportation, the lifting arm should be placed in the lowering position and screwed into the intercepting valve to avoid unnecessary wear. When screwing in and locking the intercepting valve, it should be noted that the nut of the valve rod is used for locking after screwing in the intercepting valve. When screwing out or screwing in the intercepting valve, the nut should be loosened first and retreated to the outermost end to avoid that the intercepting valve cannot be fully screwed in.

(3) Use the force adjustment handle correctly

Energy conservation by force regulation ensures a relatively uniform tillage depth and traction force, and is mainly used for farming on uneven fields. When plowing, the force adjustment method is generally adopted: first push the force and position adjustment handle back to the lifting position, then move the force adjustment handle forward, the agricultural tool starts to fall and fall into the soil. When the agricultural tool reaches the required depth of cultivation, stop the handle movement, and block the force adjustment handle with the positioning handwheel, so that the handle will be pushed to the fixed position every time the agricultural tool is lowered.

(4) Correct use of position adjustment handle

The method of position adjustment is to first place the two handles of force and position adjustment in the lifting position, and then move the position adjustment handle forward to lower the agricultural tool; The more you move forward, the more the farm tools will fall, that is, corresponding to each position of the position adjustment handle, the farm tools will also maintain a certain position relative to the tractor. The position adjustment method is generally used for rotary tillage and harrowing, harvesting, lifting, bulldozing, dump trailer and other non-arable land operations. Under the condition of flat ground and small change of soil resistance, position adjustment can also be used for plowing. When plowing, when the farming tool reaches the required depth, block the position adjustment handle with the positioning handwheel to make the farming tool fall to the same depth each time.

(5) Correctly select the connection point of the top link

When using force adjustment to control the tillage depth, the front end of the top link should be connected to the middle connecting pin; When the position adjustment is used to control the tillage depth, the front end of the top link should be connected to the lower connecting pin. It is forbidden to use the connecting pin of the upper link for traction to avoid damaging the elevator.

(6) Hydraulic output

Wade WD40~50 tractors are equipped with output oil holes to output high-pressure oil for agricultural implements or trailers. Put the force and position adjusting handle in the lowering position, remove the oil in the hydraulic cylinder, screw in the regulating handwheel of the intercepting valve on the left side of the lift, lock the force adjusting handle in the lifting position, and then screw out the oil plug plug of the output hole on the right side of the lift, install the output oil pipe assembly, and connect it with the farm tool or trailer, use the position adjusting handle to control the hydraulic output path, when it is not necessary, install the oil plug and gasket, Screw out the regulating handle of the intercepting valve to restore the lifting capacity of the elevator.