What is the bearing and its structural classification

Bearing is an important part of modern mechanical equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement, and ensure its rotation accuracy.

Bearing classification

sliding bearing

Sliding bearings have neither inner and outer rings nor rolling elements, and are usually made of wear-resistant materials. It is often used for mechanical rotating parts with low speed, light load and difficult lubrication and maintenance.

Joint bearing

The sliding contact surface of spherical sliding bearing is spherical, which is mainly applicable to swing motion, tilt motion and rotation motion.

Rolling bearing

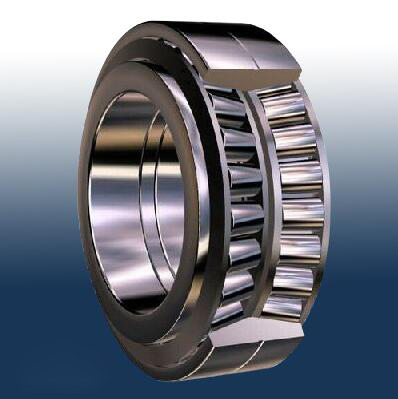

Rolling bearings are divided into radial bearings and thrust bearings according to the load direction they can bear or the nominal contact angle. Radial contact bearing is a radial bearing with a nominal contact angle of 0, and radial angular contact bearing is a radial bearing with a rated contact angle greater than 0 to 45. Axial contact bearing is a thrust bearing with a nominal contact angle of 90, while thrust angular contact bearing is a thrust bearing with a rated contact angle of more than 45 but less than 90.

According to the shape of rolling body, it can be divided into ball bearing and roller bearing. Roller bearing is divided into cylindrical roller bearing, needle roller bearing, tapered roller bearing and self-aligning roller bearing according to the type of roller.

According to whether it can be aligned during operation, it can be divided into self-aligning bearings - bearings with spherical raceways, which can adapt to the angular deviation and angular movement between the axes of two raceways; Non-self-aligned bearing (rigid bearing) - can resist angular deviation of axis between raceways.

The rolling element is divided into single-row bearing, double-row bearing and multi-row bearing according to the number of rows.

It can be divided into separable bearing and non-separable bearing according to whether its components (ferrules) can be separated.

According to its structural shape (such as whether there is a filling groove, whether there is an inner and outer ring, the shape of the ferrule, the structure of the retaining edge, and even whether there is a cage), it can also be divided into various structural types.

According to the size of its outer diameter, it is divided into micro bearings (<26mm), small bearings (28-55mm), small and medium-sized bearings (60-115), large and medium-sized bearings (120-190mm), large bearings (200-430mm) and extra-large bearings (>440mm).

It is divided into motor bearing, rolling mill bearing, main bearing, etc. according to the application field.

It is divided into ceramic bearings, plastic bearings, etc.

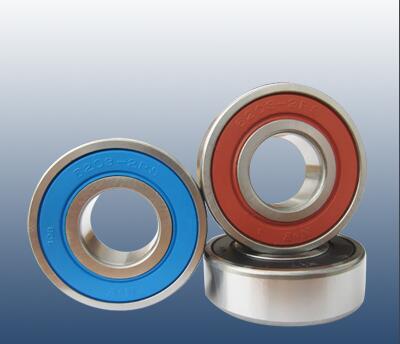

Deep groove ball bearing

Deep groove ball bearing is the most representative rolling bearing. Compared with other types of bearings of the same size, this type of bearing has small friction coefficient, high limit speed, simple structure, low manufacturing cost, high accuracy, and no need for regular maintenance. It is the most widely used bearing type, with a wide range of dimensions and various forms. It mainly bears radial load and can also bear certain axial load. When it only bears radial load, the contact angle is zero.

After the deep groove ball bearing is installed on the shaft, the axial displacement of the shaft or shell in two directions can be limited within the axial clearance of the bearing, so the axial positioning can be carried out in two positions. When the deep groove ball bearing has large radial clearance, it has the performance of angular contact bearing and can bear large axial load. Deep groove ball bearing has more advantages than thrust ball bearing under high speed operation conditions with large axial load. In addition, this type of bearing also has certain self-alignment capability. When it is tilted 2 '- 10' relative to the housing hole, it can still work normally, but it has certain impact on the bearing life.

Angular contact ball bearing

Generally speaking, the six types of bearings represented by 36 and 46 bearings have angular contact of 15 degrees, 25 degrees and 45 degrees.

Self-aligning ball bearing

Self-aligning ball bearing is a bearing with spherical ball between the inner ring of two raceways and the outer ring of spherical raceways. The curvature center of the outer ring raceway surface is consistent with the bearing center, so it has the same self-aligning function as the self-aligning ball bearing. When the shaft and housing are bent, they can be adjusted automatically without increasing the bearing burden. Self-aligning roller bearing can bear radial load and axial load in two directions. Self-aligning ball bearing has large radial load capacity and is suitable for heavy load and impact load. The inner diameter of the inner ring is a bearing with a tapered hole, which can be installed directly. Or install it on the cylindrical shaft with fixed sleeve and removal cylinder. The bracket is composed of steel plate stamping bracket and polyamide self-aligning ball bearing, which is suitable for bearing heavy load and impact load, precision instruments, low-noise motors, automobiles, motorcycles, metallurgy, steel mills, mines, petroleum, paper, cement, sugar and other industries and general machinery.

Thrust ball bearing

The thrust ball bearing is divided into one-way and two-way. They can only bear axial load, not any radial load. The thrust bearing is divided into two parts: sealing ring and movable ring. The fastening ring is closely matched with the shaft sleeve, and the movable ring is supported on the bearing seat. Ferrules and rolling bodies are usually made of rolling bearing steel with high strength and good wear resistance. The surface hardness after quenching shall reach HRC60 ~ 65. The cage is mainly made of mild steel stamping, and can also be made of copper alloy cloth laminated bakelite or plastic.

Two-way thrust angular contact ball bearing

The contact angle of thrust angular contact ball bearing is generally 60 °. The commonly used thrust angular contact ball bearing is a two-way thrust angular contact ball bearing, which is mainly used for the spindle of precision machine tools. Generally used with double-row cylindrical roller bearings, it can withstand two-way axial load. It has the advantages of high precision, good rigidity, low temperature rise, fast speed and convenient disassembly and assembly.

Thrust roller bearing

It includes thrust cylindrical roller bearing, thrust tapered roller bearing, thrust needle roller bearing and thrust self-aligning roller bearing.

Needle bearing

The needle roller bearing is equipped with slender rollers (the roller length is 3~10 times the diameter, and the diameter is generally not more than 5 mm), so the radial structure is compact, the inner diameter size and bearing capacity are the same as other types of bearings, and the outer diameter is the smallest, which is especially suitable for the support structure with limited radial installation size. The needle roller bearing can select the bearing without inner ring or the needle roller and cage components according to different applications. At this time, the journal surface and shell hole surface matching the bearing are directly used as the inner and outer rolling surfaces of the bearing. In order to ensure the same load capacity and operating performance as the bearing with ring, the machining accuracy and surface quality of the raceway surface of the shaft or shell hole should be the same as that of the bearing ring. Combined needle roller bearing is a bearing unit composed of centripetal needle roller bearing and thrust bearing components. It has compact structure, small volume, high rotation accuracy, and can bear certain axial load and extremely high radial load. The product has diverse structure, strong adaptability and easy installation. Combined needle roller bearings are widely used in machine tools, metallurgical machinery, textile machinery, printing machinery and other mechanical equipment, which can make the mechanical system design very compact and flexible.

Outer spherical ball bearing

The outer diameter surface of the outer ring of the outer spherical ball bearing is spherical, which can play the role of centering.

Spherical Roller Bearings

Self-aligning roller bearings have two rows of symmetrical spherical rollers, which mainly bear radial load and can also bear axial load in any direction, but can not bear pure axial load. The outer race of the bearing is spherical, so its centering performance is good and can compensate for the coaxiality error. When the shaft is bent or installed concentrically, the bearing can still be used normally. Centering performance varies with the size series of the bearing. Generally, the allowable alignment angle is 1~2.5 degrees. This kind of bearing has large bearing capacity. In addition to bearing radial load, the bearing can also bear two-way axial load and has good impact resistance. Generally speaking, the allowable working speed of self-aligning roller bearing is low. It is applicable to work under heavy load or vibration load.

Flange bearing

The outer ring of flange bearing is equipped with flange flange. It is characterized by simplifying the structure of the main engine, reducing the size of the main engine and making the bearing easier to locate.

Bearing with seat

Radial bearing is a component combined with valve seat. There is a base plate for installing screws on the bearing surface parallel to the bearing axis.

Combined bearing

A rolling bearing is composed of two or more bearing structures in a group of bearings. Such as needle roller and thrust cylindrical roller combined bearing, needle roller and thrust ball combined bearing, needle valve and angular contact ball combined bearing, etc.

Linear bearing

Linear bearings are divided into metal linear bearings and plastic linear bearings.

Metal linear bearing is a low-cost linear motion system, which is used to fit with cylindrical shaft with infinite stroke. Because the bearing ball and shaft are in point contact, the working load is very small. The steel ball rotates with minimum friction resistance to achieve high-precision and smooth movement.

Plastic linear bearing is a linear motion system with self-lubricating characteristics. The biggest difference between plastic linear bearing and metal linear bearing is that the metal linear bearing is rolling friction, and the contact between the bearing and the cylindrical shaft is point contact, so this kind of bearing is suitable for low-load high-speed movement; The plastic linear bearing is sliding friction, and the contact between the bearing and the cylindrical shaft is surface contact, so it is suitable for high load, medium and low speed movement.