What is the electrical system of small tractors What are the characteristics?

Various motors, instruments and electrical devices required to ensure the normal operation of the tractor.

It usually includes battery, generator (including voltage regulator), starting motor, lighting system, switch and instrument signal alarm system, etc.

(1) System composition

Battery

It is used to store electric energy and supply power to the starting motor, or supplement power supply to the electrical equipment when the generator power supply is insufficient. Generally, the battery used for tractors is lead-acid battery, which has three specifications: 6 V, 12 V and 24 V. The capacity of the battery refers to the amount of electricity discharged when the battery is discharged to a certain voltage under certain discharge conditions, measured in ampere-hours. The battery capacity shall be selected according to the power required to start the engine at low temperature, that is, the minimum starting speed and resistance torque of the engine. Tractor battery requires high starting current, good vibration resistance and suitable for low temperature use.

Alternator

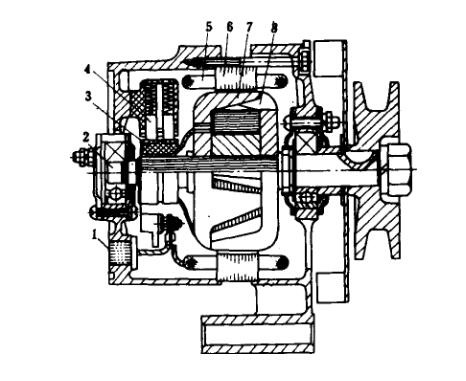

Provide electric energy to the tractor electrical equipment and charge the battery. There are three common types: ① flywheel generator. For the alternator, there are three stator windings, and the rotor is composed of six permanent magnets bonded on the steel ring, which is widely used on walking tractors. Its output voltage is related to the engine speed and the load current of the generator. When voltage stabilization is required, permanent magnet motor voltage regulator can be used. ② Silicon rectifier generator. It is an alternator (Figure 1), which is made of six silicon tubes (and nine-tube type) for full-wave rectification, and the negative pole is grounded. Its voltage regulator has vibration type or transistor type, has developed into integrated circuit regulator, and is integrated with the generator. ③ DC generator with commutator. Due to the large amount of nonferrous metals, the commutator often needs to be repaired in use, and has been phased out.

Fig. 1 Silicon rectifier generator

1. Silicon diode; 2. Shaft; 3. Collector ring; 4. Electric brush; 5. Stator coil; 6. Stator; 7. Magnetic pole; 8. Excitation coil

Starting motor

It is a series or compound excitation DC motor. When working, the electromagnet engages its drive gear with the flywheel gear ring of the engine to start the engine. When the engine speed increases after starting, the one-way clutch causes the drive gear to rotate over the shaft and disengage. In order to reduce the volume and fit the small cylinder bore engine, a high-speed starting motor with a reducer is adopted.

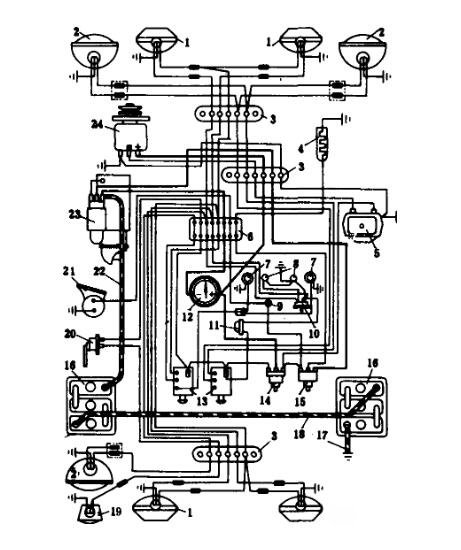

Figure 2 Tractor electrical circuit

1. Small lamp; 2. Headlight; 3. Terminal board; 4. Glow plug; 5. Regulator; 6. Fuse box; 7. Instrument lamp; 8. Turn signal lamp; 9. Horn button; 10. Turn signal switch; 11. Flashing interrupter; 12. Ammeter; 13. Two-gear switch; 14. Switch; 15. Preheating start switch; 16. Storage battery; 17. Battery grounding wire; 18. Connection between storage batteries; 19. Stop lamp; 20. Stop light switch; 21. Horn; 22. Battery to starter connection; 23. Series excitation DC motor; 24. Silicon rectifier generator

lighting

Tractors generally have headlights, steering lights, brake lights, instrument lights, work lights, etc. The illuminance of each lamp in the lighting area has certain requirements. Some tractors also have warning lights for slow vehicles, tail lights, clearance lights, cab ceiling lights, etc.

Instrument and signal alarm system

It is composed of indicator, flashlight, signal lamp and sensor. Common instruments include water temperature gauge, oil pressure gauge, ammeter, speedometer, fuel gauge, working hour meter, etc. The types of instruments include spring tube type, thermoelectric type, magnetoelectric type, etc. Modern tractors often use magneto-electric combination instruments, equipped with various sensors such as temperature, pressure, vacuum, rotational speed and oil quantity. There are two types of sensor structures: analog and switching, and the analog sensor is matched with the indicating instrument; The switch type sensor cooperates with the alarm signal lamp to give an over-limit alarm. Switch type sensors are often used for oil pressure and air filter blockage, oil and diesel filter blockage, etc. The flashing light is used to provide steering and warning signals. There are also some signal lights to indicate the tractor working conditions, such as whether the parking brake is released; Whether the front wheel drive is in gear; Whether the battery is charged; Whether the speed of the power take-off is 540 rpm or 1000 rpm, and the use of the trailer turn signal.

There are two types of tractor tachometers, mechanical transmission type and electronic type. The electronic tachometer is actually a wide-angle milliammeter. The electromagnetic speed sensor generates a pulse signal, which is converted into a current signal proportional to the speed through the circuit and sent to the milliammeter. Travel speed and PTO speed are often marked on the tachometer. This kind of watch has no transmission mechanical wear, so it is widely used. The working hour meter is generally installed in the tachometer to calculate the working time of the tractor.

With the development of electronic technology, some modern high-power tractors have been equipped with microprocessor-based instruments and detection systems, which have the functions of digital display, flash alarm, audible alarm and automatic detection, to reduce the driver's labor.

Figure 2 is a schematic diagram of the electrical circuit of a typical tractor. Except for the ammeter, other instruments and sensors are not drawn.

(2) System features

① Low pressure. The power supply voltage on the tractor is generally 6 V or 12 V. Most of them use permanent magnet alternator as power supply, which is 6~8 volts, while those using silicon rectifier generator and battery as power supply are generally 12 volts.

② Both AC and DC power supplies are available. Small tractors mainly use AC power. Most of them do not start the motor, so they mostly use permanent magnet alternator as the power supply; However, on tractors started by electric motors, direct current is used to charge the battery.

③ Single-line system. All electrical equipment on the tractor are connected in parallel. From the power supply to the electrical equipment, a common wire is used to connect, and the tractor metal body is used as another common line.

When using DC power supply, one electrode of the power supply is connected to the metal body, commonly known as "grounding". If the negative pole of the power supply is connected to the body, it is called "negative pole grounding"; Conversely, it is called "positive grounding". The electrical system of domestic cars and tractors is specified as negative grounding.

For the tractor electrical system with AC power supply, one end of the power supply can also be grounded, and the two ends of the external circuit can be connected to the body and the ungrounded outgoing line in the power supply. Generally speaking, the grounding wire is the ground wire, and the outgoing wire at the other end is the live wire.